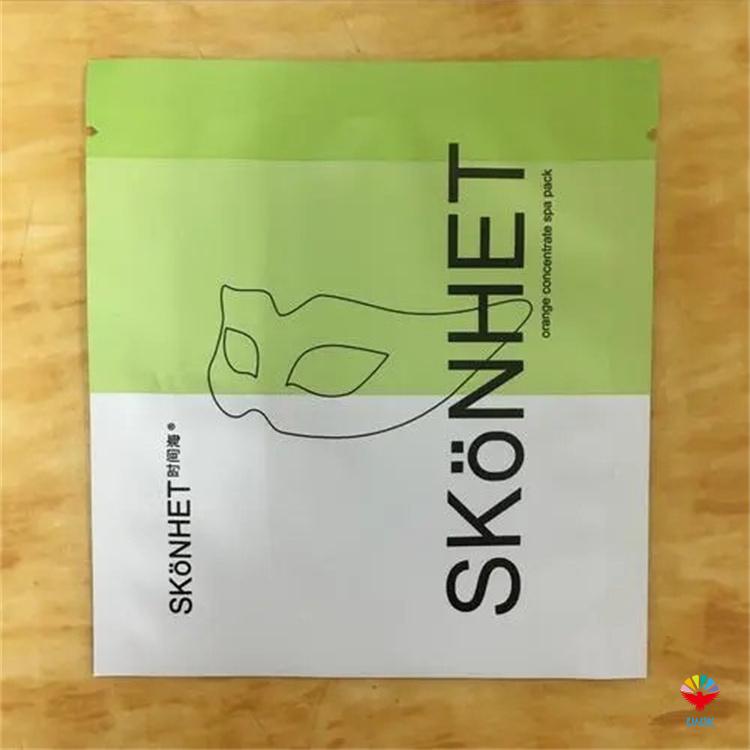

Types and production materials of self-standing zipper bags

Types of self-standing zipper bags

3.

Mechanical properties: good tensile strength, tear strength and flexibility.

5.

Hygiene and safety: complies with food safety standards and can be in direct

contact with food.

2.

Health and safety come before sports