Common problems and solutions during thermal transfer processing by printing manufacturers

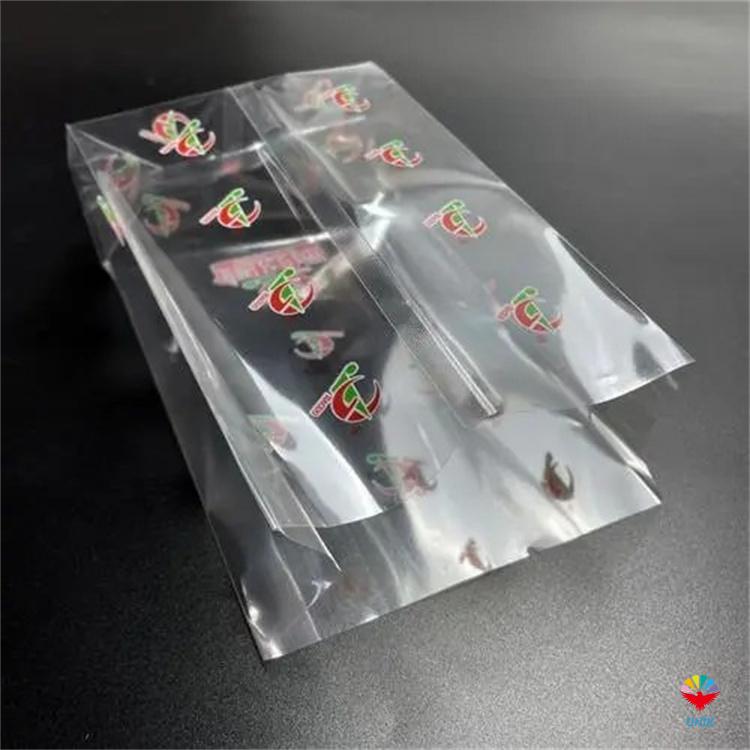

Although the price of adhesive transfer paper is too high compared to ordinary transfer paper, because it greatly reduces work efficiency, generally speaking, it is economical and cost-effective to choose adhesive transfer paper.Qingdao Unik New Material Co.,Ltd. Provides Professional Heat Transfer Film, In Mold Label And Plastic Bag Solutions, Welcome To Discuss With You.Email:sales@unikfoil.com Web:www.unikfoil.com

Mobile/WhatsApp/WeChat:+86-17669797337